PANEL STORAGE AND ASSEMBLY WAREHOUSE

Specially created to save space!

It is a new machine dedicated to the automatic deposit of vertical panels, and their subsequent assembly through a longitudinal transport line.

Perfect for all those companies that produce in medium/large quantities and would need as many spaces, but it is not possible in terms of costs, safety and... time.

You can think BIG even in a SMALL place!

The supply consists in the construction of a transport system for the handling and storage of the panels and, subsequently, also in their assembly.

The warehouse can be filled in the following ways:

- Automatic, with the aid of robotic systems;

- Manual, in which the operator deposits the panels himself on the two translating picking planes, in the panel loading station in the warehouse.

In the next phase, the operator will have to enter the type of product using one of the three different settings:

* by manually typing the product code into the terminal on the side;

* confirm from preloaded file

* by laser reader-code scanner.

After confirming the product data, the panels will automatically move to the vertical warehouse to be stacked and stored until the request for unloading or assembly.

The control station of the entire machinery is determined by the inputs set by the operator, through a system management touch terminal, which allows you to load/unload the panels and decide whether to assemble them or not, as well as other functions perfectly dedicated to the type of product of the customer.

The machine is also equipped with two side discharges:

* one on the right side, shorter, used to unload those pieces not to be assembled via a roller conveyor;

* one on the left side, with the possibility of unloading those panels that you wish to assemble, with the various accessories placed along the belt conveyors.

CONSTRUCTION MATERIALS

The brand new "vertical warehouse" is made with various specific products, according to the function of each of its parts, carefully studied in the modular forms, to be expanded according to the packages of products that the customer intends to pass through this machine:

* the entire structure is in welded and bolted steel, with powder coatings and some galvanized parts;

* the closure on the sides and top of the warehouse is created with insulating panels insulated in polyurethane;

* the rollers are made of steel and covered in pvc, and the belts in pvc.

Automation electrical panel complete with various automatisms, with Siemens S7 programmable logic, and the general control of the movements of the warehouse axes with Motion Control system.

Buttons

* Control pushbutton panel with touch operator panel in front of the general electrical panel, for automatic and manual management of the entire system;

* Operator terminal for panel data entry;

* Command push-button panel with operator panel, for unloading panels from the assembly line;

* Push-button panel for activating translation/product request on the side of the panels not to be assembled.

MEASUREMENTS

| Element | Length | Depth | Height |

| Vertical lifter with translating forks | 2750 mm | 1500 mm | 8000 mm |

| Discharge roller conveyor | 2750 mm | 900 mm | |

| Panel unloading roller conveyor not to be assembled | 2800 mm | 900 mm | 1100 mm |

| Panel unloading belt conveyor for accessory assembly, n° 3 | 2800 mm | 900 mm | 1100 mm |

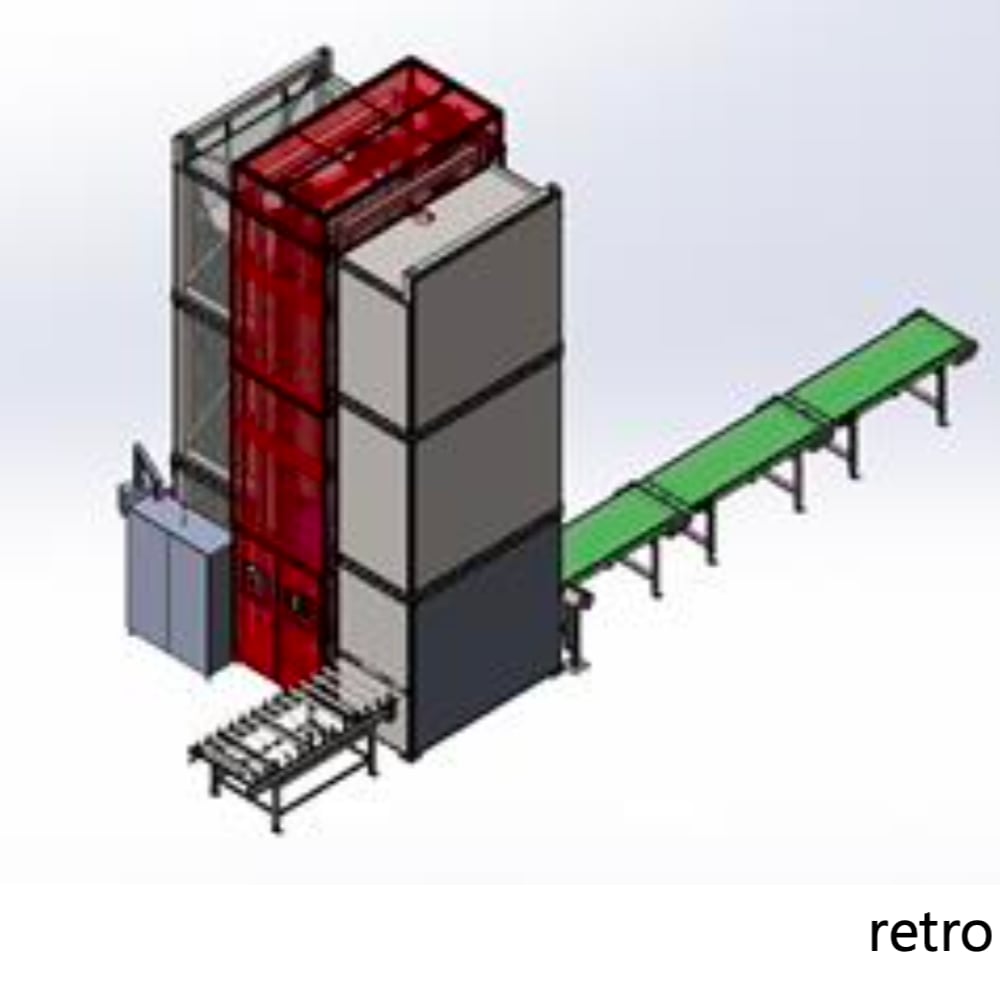

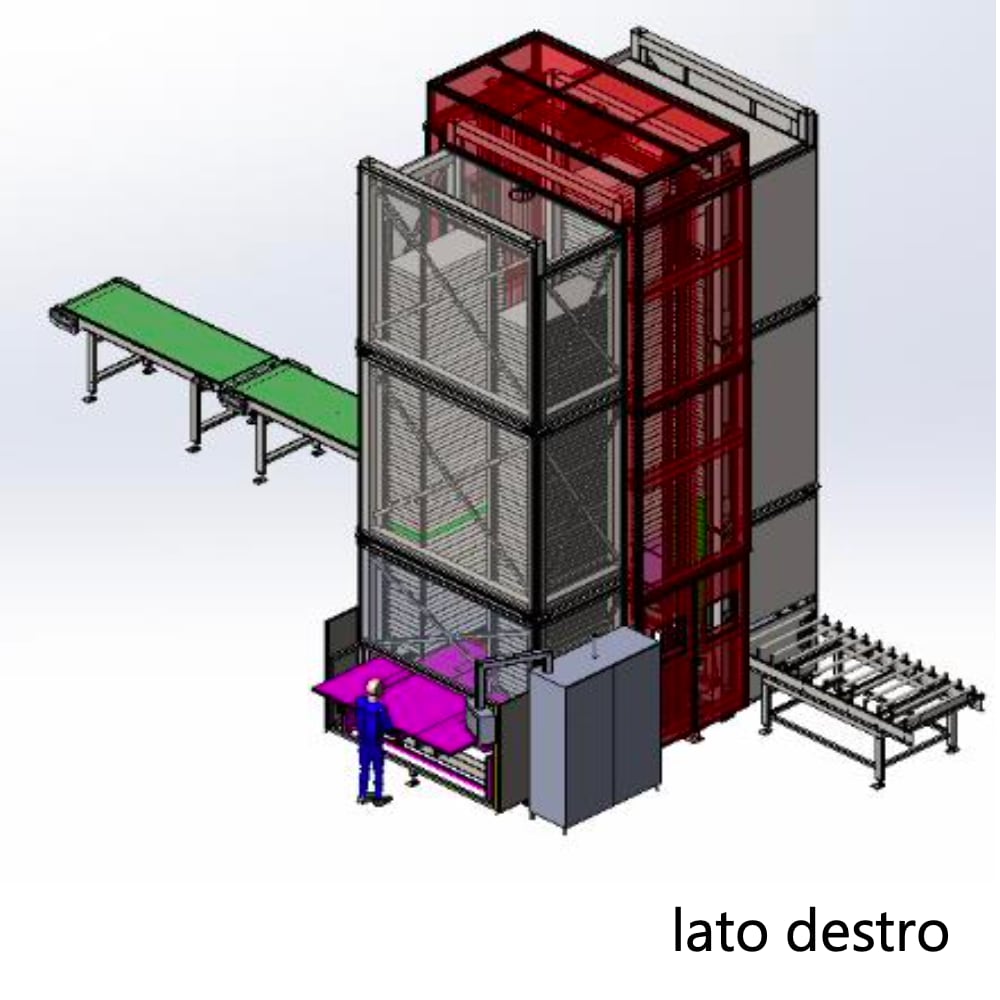

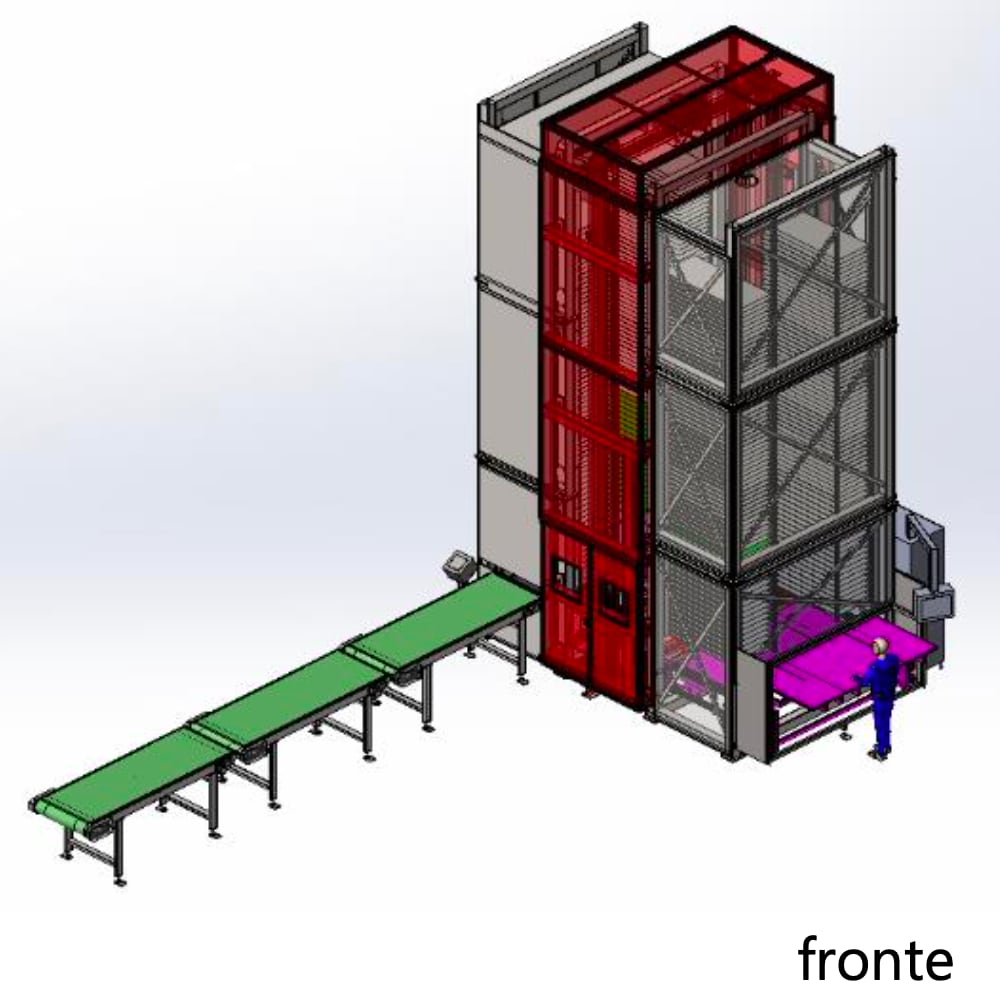

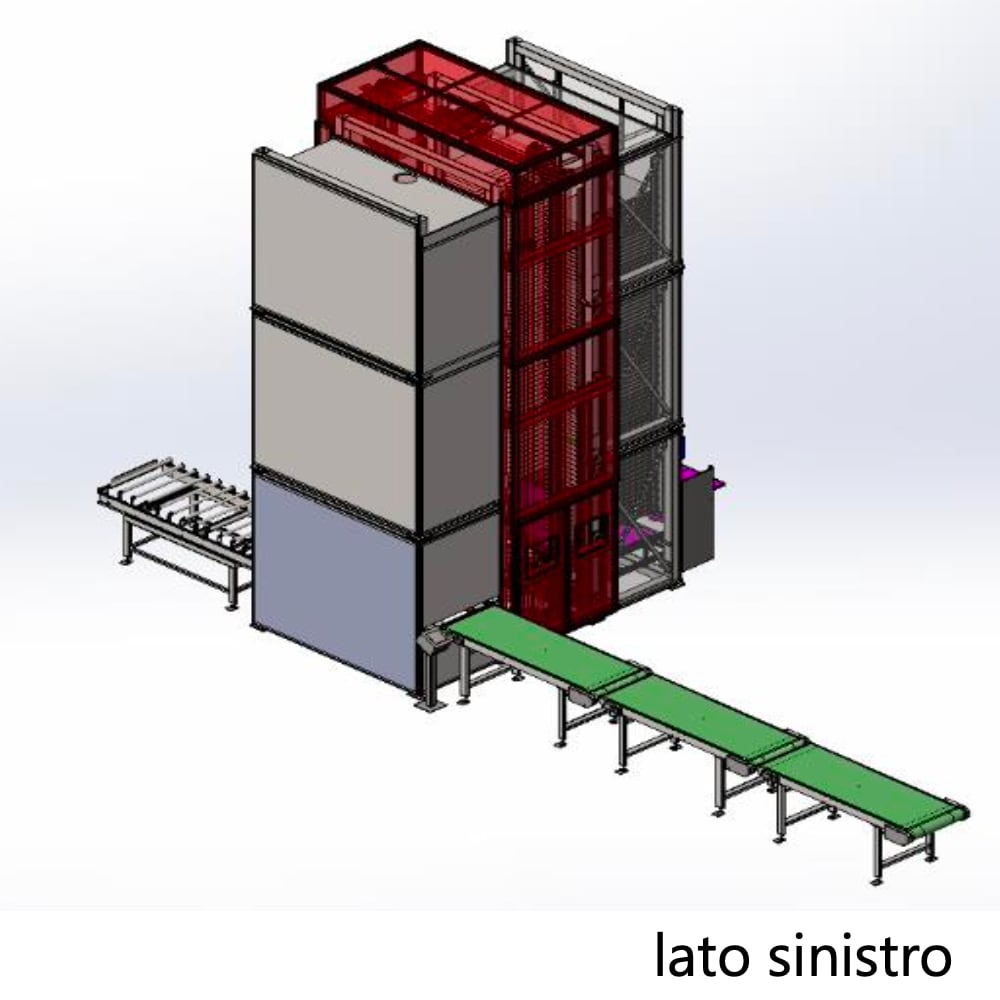

Obviously the data shown are not binding and may undergo changes based on the specific requests of the customer, in the management of their product and as the particular use deems appropriate. Below are the four views of the model of the brand new vertical warehouse.

Below are the four views of the model of the brand new vertical warehouse.

|

|

|

|

- Industrial automations

- Industrial automations

- Technological systems

- Handling and Handling

- Robotic applications

- Automatic lines

- Switchboards

- Technological systems

- Revamping

- Building special machinery

- Control systems and industrial visions

- Robotic applications

- AGV self guided vehicles

- Automatic Warehouse

- Tow trucks

- Test benches and testing

- Chemistry

- Pharmaceutical

- Industrial vision

- Wood sector

- Special Machinery

- Brick

- Leather goods

- Hydrogeological

- Special Installations

- Plastic

- Metalworker

- Paper

- Glazier

- Food-bevarage

- Logistic

- Packaging

- Galvanic